As we reported earlier in our news feed, the UNITI-EXPO 2014 exhibition allowed us to study PETROTEC’s novelties more fully. This year, a new line of 5th generation TRK – PROGRESS II was presented to the attention of customers

In this line of TRK, all model ranges are presented – the 1000, 1500, 2000, 4000 and 5000 series. Moreover, the 5000 has two versions – a low design with a hose retraction system on drums with a hose length of up to 5 meters (you can fill the far tank of the second car if there is a queue!) and the NN version with spring tensioners and hose lengths up to 3.5 m

In addition, it is possible to perform both separate and combined with the delivery of LPG (LPG – propane-butane), and with the delivery of AdBlue and heating

PROGRESS 5000 HH II PROGRESS 1000 II PROGRESS 4000 II PROGRESS 5000 II AdBlue PROGRESS 2000 II PROGRESS 5000 II LPG+ LPG PROGRESS 5000 HH II

What is PROGRESS II? This is a new functional and attractive design, of course. But, first of all, several technical innovations at once:

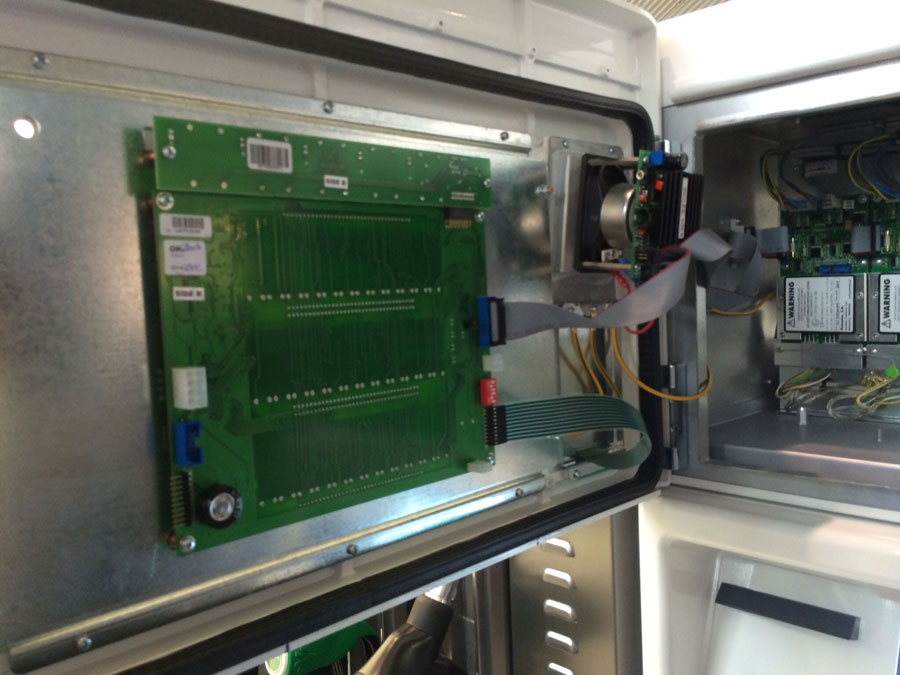

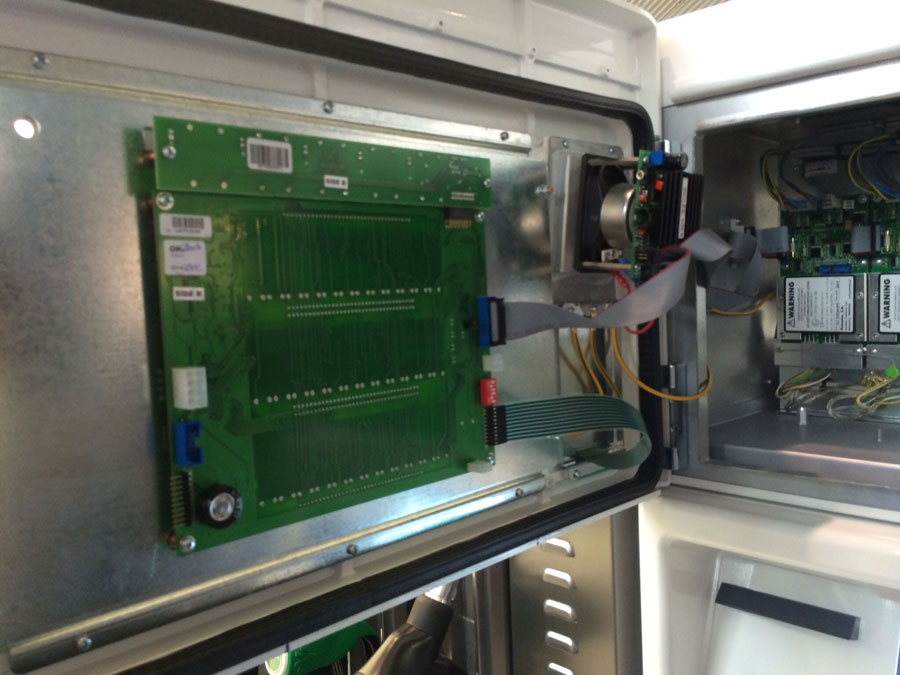

- new counting device – eMC2 – electronic modular calculator. The architecture of this device is built on a bus, which allows you to meet any special customer requirements through integration, as well as upgrade the board in the future. This calculator is certified according to the OIML/MID program. Provides flexibility of settings, the possibility of functional upgrade with a simple algorithm. Does not require large investments to adapt to local requirements and comply with the latest technological advances

- P-meter is a new volume meter (or, as professionals say, a dispenser, a volume meter, or simply a “volume meter”). This is the next step in the development of piston dispensers with a new standard of measurement accuracy – +/-0.1%! Twice as accurate as the competitors!!! The four-piston dispenser, in addition to accuracy, has a number of advantages with the two-piston system and screw dispensers of competitors. This design provides high reliability, dose stability (no drift) due to lower sensitivity to particles in the fuel. All elements have self-lubricating ability and are made of high-quality, specially selected materials. Internal pressure losses are less, internal overflows are reduced so much that it allowed us to make 1 dispenser for productivity from 40 l/min to 130 l/min (we have the same spare parts!). And this is not the result of critical performance enhancement technologies from competitors! Moreover, the design of the volume meter provides for the absence of a barrier between the pulse generator and the meter. The pulse generator is integrated into the meter. This not only prevents potential fraud, BUT also allows you to do electronic calibration at the meter level; issue a unique electronic serial number; have a built-in total counter for the entire number of liters passed through the meter; issue an error log and a calibration log, with the date, the number of liters of technological spill and calibration factor! All this is at the level of the meter, not the “head” of the gas station. Now it is easier to detect a thief in the gas station staff, and you can replace or repair the meter at the right time.

- P-pump is a new generation of gear pumps. Provides productivity from 40 l/min to 130 l/min. Efficient air separator, excellent self-priming capability. Provides a direct connection to the P-meter, without additional pipes. All internal channels are optimized to reduce pressure losses and increase efficiency. All regulating devices are located in places convenient for service. It includes a first-class reusable stainless steel fuel filter with a fineness of 100 microns, as well as an optional filter with a fineness of 30 microns.

- ATC is an automatic temperature compensation system. The eMC2 electronics allows the integration of Automatic Temperature Compensation (PBX) connected to a temperature sensor developed by PETROTEC. In addition to the excellent sensor element, the temperature sensor operates in digital format, providing perfect integration in any operating environment. Being integrated into eMC2, the PBX provides the ability to display the uncompensated volume level, compensated volume, liquid temperature on the main display of the fuel pump without additional service tools or information outputs. This is a great verification and calibration tool!