It’s no secret that fuel leaks in tanks and pipeline systems pose a direct threat to the environment and human health. Despite the differences in the legislation of different countries, the full responsibility of the owner for the damage caused when fuel enters the soil or water as a result of leakage is common.

Leak detection standards (EN 13160 1-7) were first developed for pan-European application more than 10 years ago. EN 13160 1-7 defines 5 classes of Leak control Systems. Joost Berg (CEO of SGB Gmbh, the world leader in the production of fuel leak monitoring systems), in his recent interview with PetrolPlaza portal, noted that only Class 1 and Class 2 systems allow full control and risk reduction at gas stations.

What is the difference between these classes?

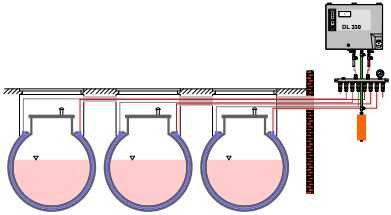

Class I: Systems operate using air pressure or compressed nitrogen, or by applying a vacuum in the interior space. Leaks are detected above or below the liquid level in a double-walled system, ensuring that there is a “test pressure” on the tank throughout the entire service life. Once a leak is detected, the fuel can be removed from the tank before it enters the environment.

Class I: Systems operate using air pressure or compressed nitrogen, or by applying a vacuum in the interior space. Leaks are detected above or below the liquid level in a double-walled system, ensuring that there is a “test pressure” on the tank throughout the entire service life. Once a leak is detected, the fuel can be removed from the tank before it enters the environment.

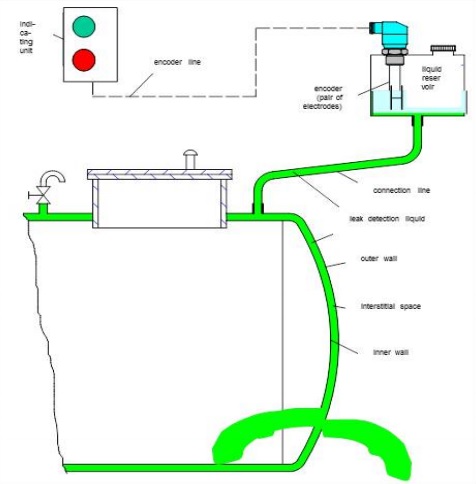

Class II: The systems operate with a liquid-filled in-port space based on the pressure generated by the height of the pressure tank above the storage tank, creating sufficient pressure to detect a liquid leak leading to a drop in the liquid level in the pressure tank, indicating the presence of a leak through any tank wall. After a leak has formed in one of the walls of the tank, the liquid either flows into the tank and contaminates the product, or gets into the soil – in both cases, contamination cannot be prevented. The main component of the liquid used in the courtyard space is “environmentally friendly” antifreeze, however, as standards and awareness increase, it is increasingly common to believe that the leak detection liquid pollutes groundwater and drinking water. In addition, it turns out that some liquids that have been used for many years can lead to fungus, algae or gelatinization, thereby interfering with the functions of the liquid to detect leaks.

Class II: The systems operate with a liquid-filled in-port space based on the pressure generated by the height of the pressure tank above the storage tank, creating sufficient pressure to detect a liquid leak leading to a drop in the liquid level in the pressure tank, indicating the presence of a leak through any tank wall. After a leak has formed in one of the walls of the tank, the liquid either flows into the tank and contaminates the product, or gets into the soil – in both cases, contamination cannot be prevented. The main component of the liquid used in the courtyard space is “environmentally friendly” antifreeze, however, as standards and awareness increase, it is increasingly common to believe that the leak detection liquid pollutes groundwater and drinking water. In addition, it turns out that some liquids that have been used for many years can lead to fungus, algae or gelatinization, thereby interfering with the functions of the liquid to detect leaks.

In the case of underground reservoirs, a more informed user prefers reliable and trouble-free detectors of Class I. Moreover, the only type of detectors, the use of which is allowed by the legislation of most European countries, are detectors of Class I. In particular, such giants as BP, Shell and other industry leaders use only Class I systems, because they take their obligations to ensure industrial and environmental safety seriously.

You can get detailed advice on all your questions by phone +7 (495) 739-25-10 or info@ligir.ru

A company that is part of the “System Group” holding. The company’s divisions are headquartered in Moscow (Russia) and Kiev (Ukraine).

Copyright © Ligir 2023 All rights reserved. Website created by WEB-studio In-Look